|

The Virtual Corkscrew Museum's Weekly Newspaper |

|

|

The Virtual Corkscrew Museum's Weekly Newspaper |

|

|

Sunday, December 13, 2009 |

Number 588 |

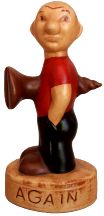

Maxram

The Maxram picnic style corkscrew was made by the wealthy Aeschliman family in Thun (near Bern), Switzerland. Max Aeschlimann invented the Maxram in the 1950s. Max suffered a heart attack in 1967 Then his two sons, Hans-Ulrich and Peter, ran the company under the name Gebr. Aeschliman. Max passed away in 1971 at the age of sixty-seven.

The firm was incorporated as Gebr. Aeschlimann AG on February 25, 1975. It was registered in Bern, Switzerland on May 22, 1975. At that time the company was listed as "Manufacture and distribution of technical innovations in the field of automobile, motorcycle and bicycle accessories, from hardware and household items and giftware, trade in light bulbs and electrical products, exploitation of patents. " The comapny was dissolved on June 15, 1999.

The Maxram began selling in the mid 60s. By 1975 over two and a half million had been sold. The patent expired in 1975 and by then there were at least two Italian imitations on the market. It was these poor imitations that eroded the Swiss firm's market. The Swiss brothers decided to cease production at that time. They didn't really need the money so the Maxram just disappeared. An American distributor, Franmara, started its business with the introduction of the Maxram.

Max Aeschlimann obtained Swiss Patent No. 355,044 for his "Deckverschluss-Öffner" (bottle opener) folding out from the side of the shank. Although he applied for the patent on August 29, 1957, it was not published until July 31, 1961.

Aeschlimann obtained Swiss Patent No. 369,277 for the triangular blades on the double helix. He applied for this patent on January 29, 1958 and it was not published until June 15, 1963.

The triangular twin spiral bites into the cork and starts the cork turning. You simply "unscrew" the cork from the bottle in a continuous clockwise motion.

It is interesting to note that Aeschlimann applied for a German patent on the bottle opener on May 28, 1958 and patent number 1,771,391 was quickly published on July 31, 1958 almost three years before the Swiss patent. The French also beat the Swiss on publishing the bottle opener patent (number 1,200,605). He applied for that patent on July 23, 1958 and it was published on December 23, 1959.

Aeschlimann also obtained French patent (No. 1,201,854) for the triangular blades. The application was filed on August 26, 1958 and published on June 1, 1960.

The Swiss Maxram is most commonly found in orange. At top right is a yellow example.

Markings on the Swiss made Maxram (both sides).

Pat. Ang. = Patent Angemeldet (Patent Pending).

Also know without Schweiz Pat. Ang. on opposite side.

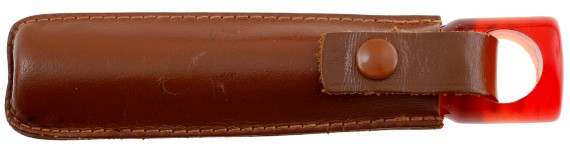

Swiss Maxram in pouch.

Made in the Swiss style but with German DBGM marking.

On June 18, 1976 Robert K. Marceca of New York applied for a U. S. Patent for his "Combined Corkscrew and Can Opener or Similar Article." U. S. Design Patent No. 247,279 was issued February 21, 1978. The patent refers to the French patent 1,201,854 and an Italian patent 473,156 (July 1952) but there is no mention of the Swiss or German patents. The patent drawing is the spitting image of the Swiss patent without the folding bottle opener. Instead it has an opener cut into the shank.

These two are made like Marceca's U. S. patent. They are marked PATHOS SUPER MADE IN GERMANY. The worms on the yellow example are round and not triangular. The orange handle example has the triangular worm.

Three different colors "Pathos" from Richard Wielpütz, Solingen.

The orange has a straight shank with no opener cutout.

The Pathos models have ribbed tops.

German models also found with only MADE IN GERMANY mark.

Italian copies of the Swiss version. Note the difference in the shape of the bottle opener. One is marked MADE IN ITALY, IRWINWARE. Irwinware was a housewares brand name sold in the United States. The other is marked R. P. L. ITALY.

Argentinian model in the style of the Marceca patent. Marked BASTION IND. ARG.

In the Swiss style marked only E. B. on the top.

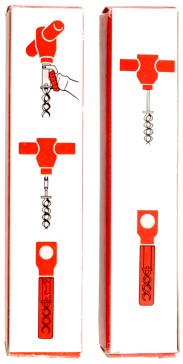

A box from Italy and the original Maxram box from Switzerland.

Graphics on the Italian box do not show the cap lifter.

The Maxram can also be found with advertising. These Swiss models advertise "Constructa" and "Osram".

Three with advertising on the tops.

"The Bar Butler" as sold by Irwinware in the U. S. A.

Heavy bronze fish marked MAXRAM SWISS MADE on one side and SCHWEIZ PAT. ANG. on the other.

Duck marked D. P. H. INDUSTRIA ARGENTINA.

Wine Otter Interview

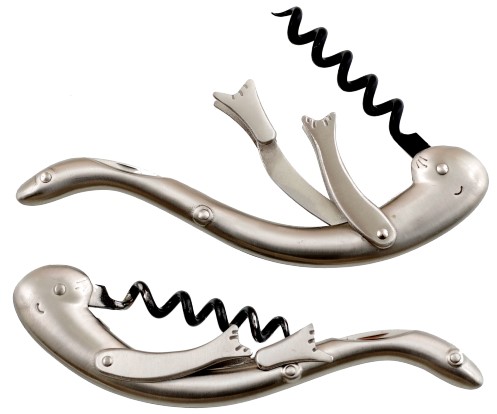

A December 9 interview with Brent Warner, inventor of the Wine Otter (see last week's issue for more).

Weekly Screw (WS): What was the inspiration for your invention?

Brent Warner (BW): On Bainbridge Island overlooking Puget Sound one fall day opening some wine for my lady friend and me. It struck me that a squeeze would be more fun than a lift and offer more control for small people. But the real inspiration was my father. He loved to tinker with thoughts and mechanical things. The name 'Wine Otter' was inspired by a friend whom I showed my initial machined corkscrew to. They laid it on its back and spun it around and said it looked like an otter. Hence the name and the look.

WS: Are you Engineer?

BW:I have a B.S. in Mathematics from Steven's Institute of Technology. Doctor of Chiropractic from Western States Chiropractic College.

WS: Do you have other inventions / innovations?

(BW): Yes. I self published a book on the creation of everything. Due to the process of writing down my hard won philosophy I found out that I was a 'Mathematical Realist-Platonist-Spinozian' philosopher. But I have come about similar conclusions from a slightly different direction. An e-book can be purchased at www.themetaphysics.com 4.

WS: How many wine otters have been produced?

(BW): Between 90-100. All cast stainless steel.

WS: Where are the wine otters manufactured?

(BW): Taiwan. I have a good friend who is skilled in managing people and businesses. He helped me get this small batch manufactured rather than turning into a relations disaster.

WS: Have you found a company to mass produce and distribute the wine otter?

(BW): The Wine Otter needs to be redesigned. To give it a sleek look of an otter we kept it narrow, and one fulcrum was mounted internally, but that precluded the use of a typical spring. So I used magnets to lock the helix in place. Most people have a hard time with this and wind up bending the helix during use. The other design mistake I made was to use cast stainless steel. The metal requires a very high temperature and consequently has a lot of tension in it, so it tends to twist and deform during cooling. This created a high rejection factor and was hard for the manufacturer to want to deal with. Now mind you, I went into using stainless steel because I was told that it would work by those that actually cast stainless steel. Future Wine Otters will be made in the normal way corkscrews or pocket knives are made layered out of stamped metals and woods.

WS: Do you have an estimated cost of manufacture and projected retail price?

(BW): What we have is all that will be made for the time being. They were intended to be high end, but I am not satisfied with the finished quality; but since they are the only corkscrews I know of that have my patent and the only ones that use magnets I consider them collectors items and will sell them for $120.

WS: Any additional comments?

(BW): Yes. Be wary of the patent office. We filed in November of 2002 and did not receive the patent until November 2009. The process was broken up into two phases. The initial patent examination, done by a 'patent examiner', and then secondly to an appeals board. The patent examiner rejected our patent because of the Subito, a corkscrew made in France in the 1800's which has a very similar shape to the Wine Otter. The difference being that the Wine Otter has two fulcrums, a short and a long, and the Subito only has one long fulcrum. The magic of the short fulcrum is that when the corkscrew is initially fully inserted and the short fulcrum engaged the bottle neck and the corkscrew handle are at an angle of less than 80 degrees, this then allows them to be squeezed together with one hand, even if the hand is small. The Subito with its one long fulcrum place the fulcrum at an angle greater than 90 degrees to the bottle neck. This then requires a downward leverage action that also requires the wine bottle to be stabilized against a table. To myself and everyone else the improvement was obvious. And by patent law since no one else did a type I lever corkscrew with two fulcrum lengths, it was not an obvious improvement and therefore not allowed. We fought the patent examiner and she finally capitulated to that but then she said, and this is almost direct quote, "A Giant hand could use the Subito as I described the use of the Wine Otter." So the mystery became for me, who designs common household utensils for Andre the Giant, even though Andre the Giant has gone onto that great wrestling match in the sky? The final patent examiner rejection was roughly around November of 2005. Then we sent it the appeals board. It took them three and a half years to say "No one designs common hand tools for only giants. Give him the patent." So the moral of the story is if I happen to invent an antigravity device, I will likely not expect much cooperation from the U. S. Patent Office.

WS: Thank you Brent. Let's open a bottle of wine with the Wine Otter!

Editor's note: Visit the Wine Otter online at http://www.wineotter.net/

Clarence O'Brien Revisited

The lead article in the September 20, 2009 edition of The Weekly Screw was about patent attorney Clarence O'Brien and his Patent Guide for the Inventor. We pictured a two frequently found advertising letter openers from O'Brien. David L. Fiol, an attorney in San Rafael, California, submitted photos of yet another O'Brien letter opener noting that this one also includes the name of Hyman Berman.

|

©2009 Don Bull, Editor |